3D printing vs CNC machining are both popular manufacturing processes that offer a variety of benefits for businesses. So, which one is the best choice for your business? It will depend on several factors.

It includes the type of product you’re manufacturing, the quantity you need, and your budget. CNC machining is ideal for products that require high precision and intricate details. It’s also a good choice for manufacturing large quantities of parts.

3D printing is best suited for prototypes and small-batch production. It’s also more affordable than CNC machining. Making it a good choice for businesses on a tight budget.

Ultimately, the best manufacturing process for your business depends on your specific needs and requirements. If you’re not sure which process is best for your product, it’s always a good idea to consult with a professional manufacturer like Tekcel. We can help you determine the best manufacturing process to meet your needs and requirements.

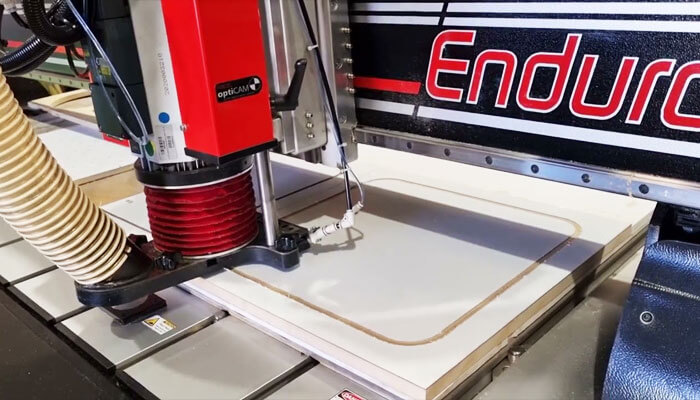

A CNC machine is a computer-controlled machine that can be used to cut or shape metal, wood, or other materials. The machine uses a cutting tool to remove material from the workpiece. The cutting tool itself can be a router or milling machine.

CNC machines are typically used in manufacturing and industrial applications. However, they can also be used for hobbyist or home workshop projects. CNC machines are available in a wide range of sizes and prices, from small desktop units to large industrial machines.

Some CNC machines are even able to create three-dimensional objects.

CNC machining has several advantages over traditional machining methods:

However, there are also some disadvantages to CNC machining:

The “Pros and Cons of CNC Machining” Infographic is available to download here:

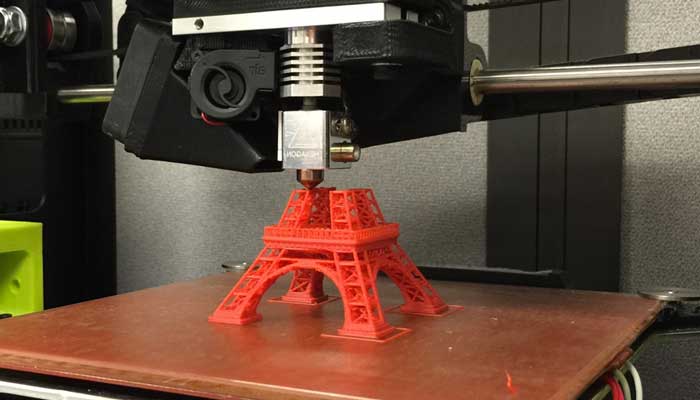

3D printing is a manufacturing process that creates three-dimensional objects from a digital file. It is also known as additive manufacturing because it builds objects by adding layers of material. 3D printing has become increasingly popular in recent years due to its advantages:

However, there are some drawbacks to this technology:

As a result, 3D printing will likely become an increasingly important part of manufacturing in the years to come.

When it comes to finding a quality CNC router in Australia, businesses can trust Tekcel. Tekcel has a proven track record of providing high-quality machines. Customer service excellence is our backbone.

We offer a wide range of CNC routers to suit any budget and application. And we are always on hand to provide support and expert advice.

Whether you need a machine for simple woodworking or complex metal fabrication, Tekcel has a CNC router to suit your needs.

So if you’re looking for a quality CNC router, reach out to Tekcel.